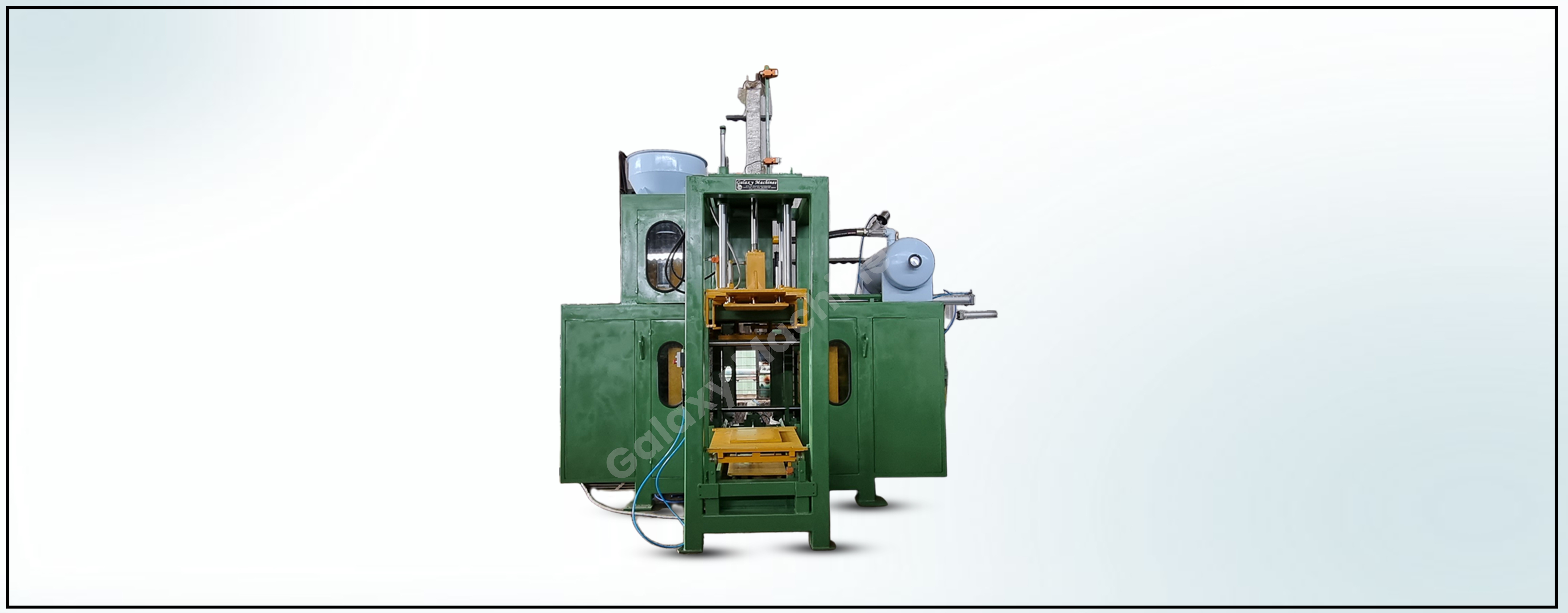

The universal cold box core shooter machine combines features of both vertical and horizontal parted machines. This makes the machine unique and gives capability to mount both vertically or horizontally parted core boxes. This type of machine is particularly suitable for making large cores in lower quantities. We manufacture universal box machines with varying capacities up to 120 kg.

In vertical operation, both the halves of the core box are moving. A carrier trolley is provided with mandrel mounted on it. As the cycle starts, the mandrel trolley moves in and the two halves of core box clamp together. After completion of the cycle, the core comes out of the machine on mandrel carrier trolley. The core can be collected by the operator. In horizontal operation, the bottom half of the core box is fixed on the carrier trolley. The top half is lifted with the help of top lifter assembly. As the cycle starts, both halves of core box enter machine on the core carrier trolley. Then LH and RH mandrels clamp with the core box. After completion of the cycle, the core carrier trolley comes out. The top half is lifted by top lifter assembly. The core can now be collected by the operator from the bottom half.

In vertical operation, both the halves of the core box are moving. A carrier trolley is provided with mandrel mounted on it. Additionally, a rear mandrel is provided. As the cycle starts, the mandrel trolley moves in and the two halves of core box and the rear mandrel clamp together. After completion of the cycle, the core comes out of the machine on mandrel carrier trolley. The core can be collected by the operator. In horizontal operation, the bottom half of the core box is fixed on the carrier trolley. The top half is lifted with the help of top lifter assembly. As the cycle starts, both halves of core box enter machine on the core carrier trolley. Then LH, RH and rear mandrels clamp with the core box. After completion of the cycle, the core carrier trolley comes out. The top half is lifted by top lifter assembly. The core can now be collected by the operator from the bottom half.