This is a high productivity machine which manufactures cores almost at double the rate than of single station machines. We manufacture double station machines of varying capacities of up to 80 kg per station.

The vertical machine consists of single core box and two mandrels mounted on a single mandrel carrier trolley. When the first mandrel moves in, the core box clamps and the operation starts. When the core is ready, the first mandrel moves out along with the core. At the same time, the second mandrel moves in the machine and the operation repeats. While the operator collects the core from the first mandrel, the core of second mandrel is ready. As the operator now collects core from second mandrel, the operation on the first mandrel begins. The mandrel carrier trolley keeps on shuttling to both sides of the machine. The cores are collected from both sides of the machine. This arrangement gives twice the rate of production for almost same cycle time of single station machine.

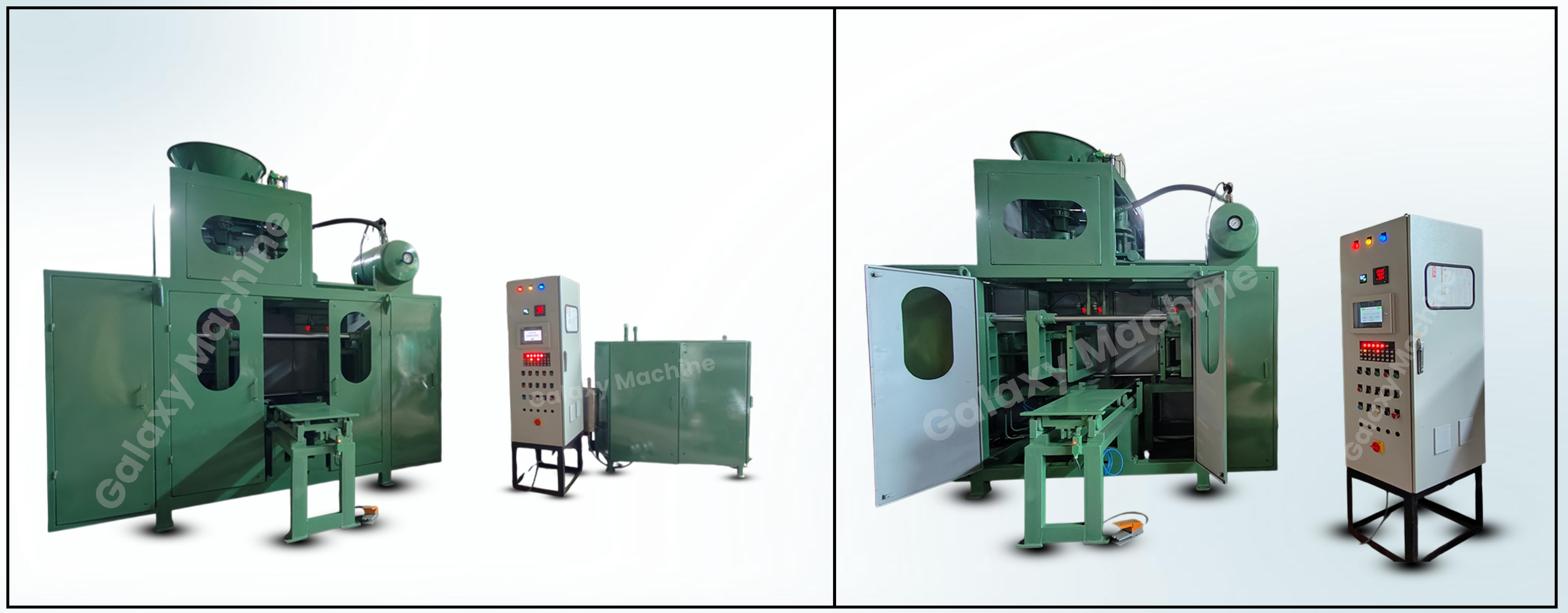

The horizontal machine consists of two core boxes. Both the bottom halves are fixed on the carrier trolley. Two top lifter arrangements are provided on both sides of the machine. As the first core box moves in, the operation starts. When the core is ready, the first core box moves out of the machine. The lifter lifts the top half for core collection. Simultaneously, the second core box moves in the machine and the operation repeats. While the operator collects core from first core box and cleans it, the core in second core box is ready. The carrier trolley keeps on shuttling to both sides of the machine. The cores are collected from both sides of the machine. This arrangement gives twice the rate of production for almost same cycle time of a single station machine.