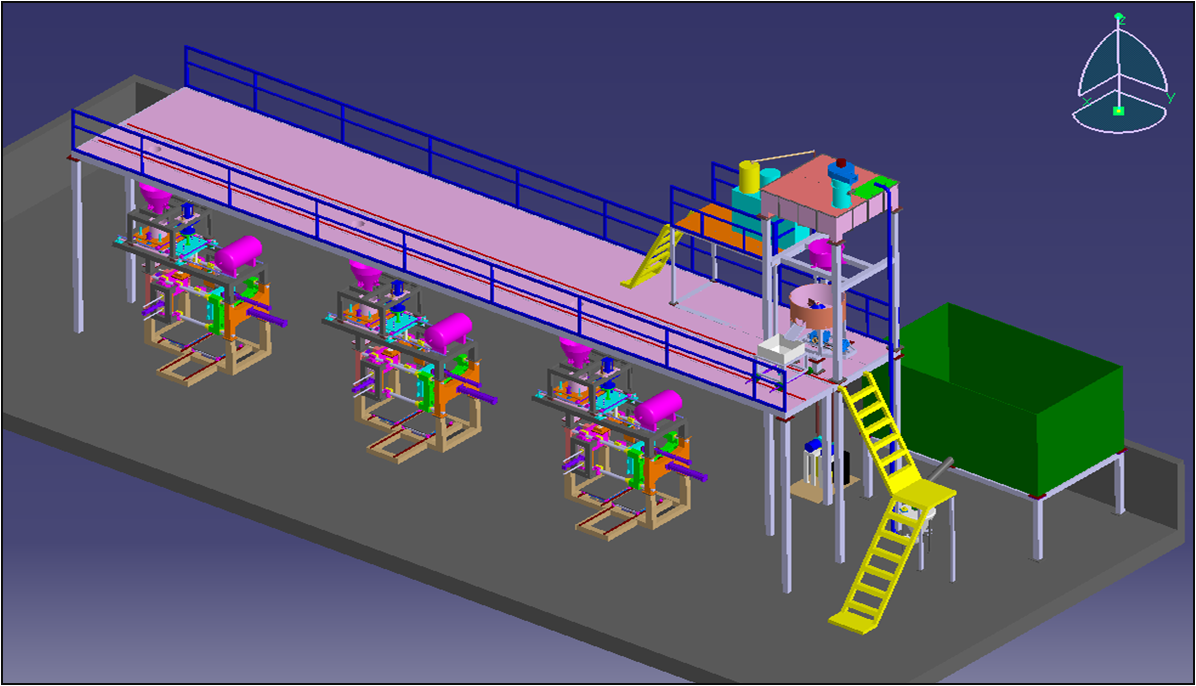

Galaxy manufactures fully automatic sand preparation plants that can provide sand mixed with chemicals for up to 10 core shooter machines. The plant contains a large sand storage unit or a sand pit at ground level. The sand it pumped to the top of unit by a pneumatic sand conveyor or by a bucket elevator. This sand falls into the main cylo. A dust collector mounted on the main cylo collects flying sand particles avoiding any air pollution. This sand then is let into the batch hopper. The batch hopper contains three load cells to accurately weigh the incoming sand. This batch of sand is then let into the sand mixer. The binder dosing system feeds the mixer with resin and hardener in precise quantity according to the weight of sand. Once the sand mixing is complete, the mixture is deposited in the sand discharge trolley. The automation system is connected to the machines underneath via PLC control. When the hopper of a particular machine is empty, it sends a signal to the sand discharge trolley. The trolley travels to this particular machine and provides the necessary amount of sand.